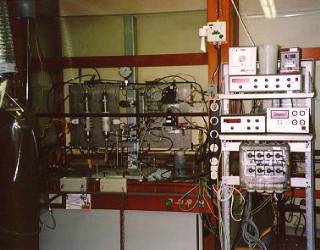

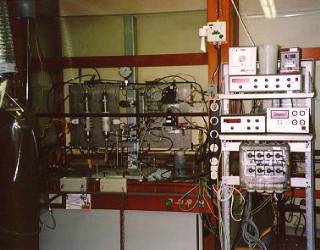

When designing a fast fluid bed (see figure) the most important parameters are porosity, mass transfer and contact-efficiency. The goal of this research was to investigate mass transfer and contact-efficiency between the gas phase and the particles in a riser. Therefore experiments were carried out in a laboratorium, using a quartz circulating fluid bed reactor (diameter 15 mm, length 117 cm) placed in a oven. By use of a probe gas samples could be taken from within the reactor at several heights. The porosity along the reactor was calculated from the pressure profile. External mass transfer was measured using the oxidation of carbon monoxide to carbon dioxide as a model reaction. The reaction was activated by a platina catalyst at a gamma-alumina carrier (dp=65 µm). Inert carrier was added to the active catalyst to achieve usable conversions.

When designing a fast fluid bed (see figure) the most important parameters are porosity, mass transfer and contact-efficiency. The goal of this research was to investigate mass transfer and contact-efficiency between the gas phase and the particles in a riser. Therefore experiments were carried out in a laboratorium, using a quartz circulating fluid bed reactor (diameter 15 mm, length 117 cm) placed in a oven. By use of a probe gas samples could be taken from within the reactor at several heights. The porosity along the reactor was calculated from the pressure profile. External mass transfer was measured using the oxidation of carbon monoxide to carbon dioxide as a model reaction. The reaction was activated by a platina catalyst at a gamma-alumina carrier (dp=65 µm). Inert carrier was added to the active catalyst to achieve usable conversions.

After making an Arrhenius plot is was concluded that at temperatures above 400 °C mass transfer was mainly the limiting mechanism. Mass transfer was measured using a thinning of the catalyst of n=500 m3inert/m3catalyst with the following results:

When assuming that catalyst particles agglomerate and form spherical clusters with a diameter dcluster and a porosity ecluster, two cluster models can be made. One model to describe the hydrodynamics and one to describe the mass transfer in the riser. Each model can be simplified to one equation with two unknowns (dcluster and ecluster). When combining both models a unique solution can be found for both unknowns.

Application of the combined model on the results of the current research and on literature data indicates that the clusters are very large and porous (dcluster=10 mm, ecluster=0.9). The influence of thinning the active catalyst with inert carrier can be modelled very well in that case (see figure).

When assuming that catalyst particles agglomerate and form spherical clusters with a diameter dcluster and a porosity ecluster, two cluster models can be made. One model to describe the hydrodynamics and one to describe the mass transfer in the riser. Each model can be simplified to one equation with two unknowns (dcluster and ecluster). When combining both models a unique solution can be found for both unknowns.

Application of the combined model on the results of the current research and on literature data indicates that the clusters are very large and porous (dcluster=10 mm, ecluster=0.9). The influence of thinning the active catalyst with inert carrier can be modelled very well in that case (see figure).Further investigation to the validity of the cluster model is recommended.